At Sonnarkraft, powder coating is not just a surface treatment — it’s a production-critical process that impacts product performance, brand image, and compliance. We specialize in automated, high-throughput powder coating solutions tailored for global OEM and Tier 1/2 clients.

What Sets Us Apart:

1. Fully Automated Electrostatic Coating Lines

Equipped with WAGNER (Germany) and GEMA (Switzerland) systems, our lines support steel, aluminum, large-size components, and complex geometries.

2. No Sandblasting Required

We use an Atotech spray-based pretreatment system, offering strong oil-free surface cleaning without abrasive blasting. This ensures high coating adhesion while preserving substrate integrity.

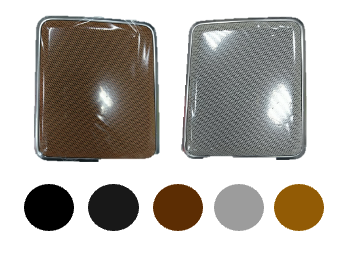

3. Consistent Coating Quality

Digitally controlled powder output and voltage regulation ensure stable film thickness, even color, and superior transfer efficiency across every batch.

4. Supported Part Dimensions

Maximum Part Size: 190 cm (L) × 60 cm (W) × 15 kg

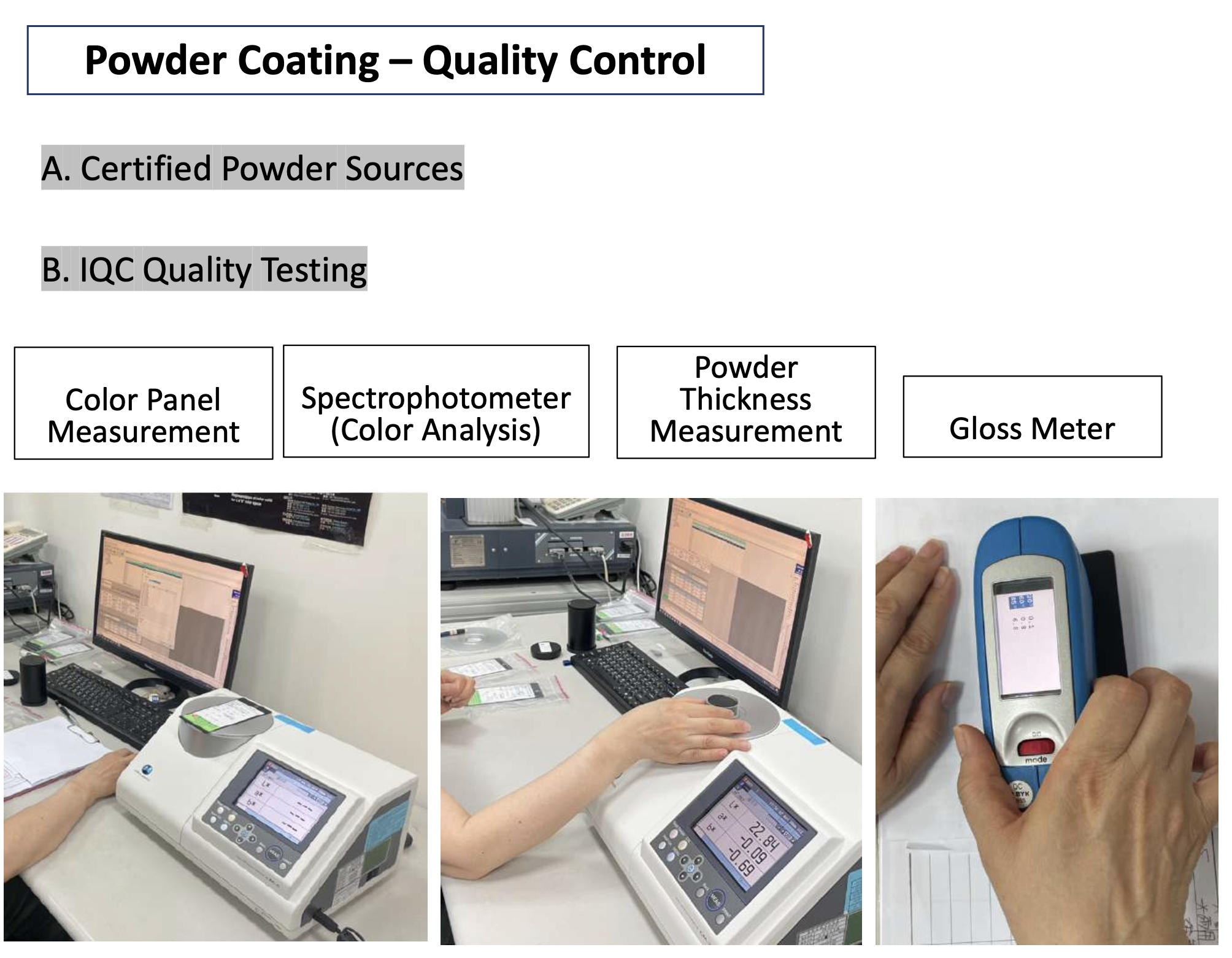

In-Process Quality Control:

Our quality assurance is built into the process. Each batch is verified with

- Spectrophotometer & Gloss Meter Readings

To ensure color accuracy and finish consistency

- Adhesion & Durability Testing

Including cross-cut, impact, and salt spray testing

- Thickness Reports & Batch Documentation

Available upon request for quality audits or internal review

Sustainable Coating from Day One:

- Eco-Compliant Materials:

- All powder materials used are RoHS and REACH compliant

- Environmentally Certified Facility:

- Our factory operates under the ISO 14001 environmental management system