Automotive Stamping, Engineered in Taiwan.

De-risk your supply chain and accelerate your time-to-market. Sonnarkraft’s fully integrated facility in Taoyuan, Taiwan, combines tooling, precision stamping, and powder coating under one roof. We eliminate subcontractor dependencies to guarantee quality, shorten lead times, and deliver complex components with absolute consistency.

THE SONNARKRAFT ADVANTAGE: A MORE RELIABLE STAMPING PARTNER

-

IATF 16949 Certified & OEM-Trusted Quality:

-

Our processes are validated by world-class automotive brands like BMW, Audi, and JLR. We provide complete ERP-driven traceability from raw material to final inspection, ensuring every part meets the most stringent quality standards.

-

-

-

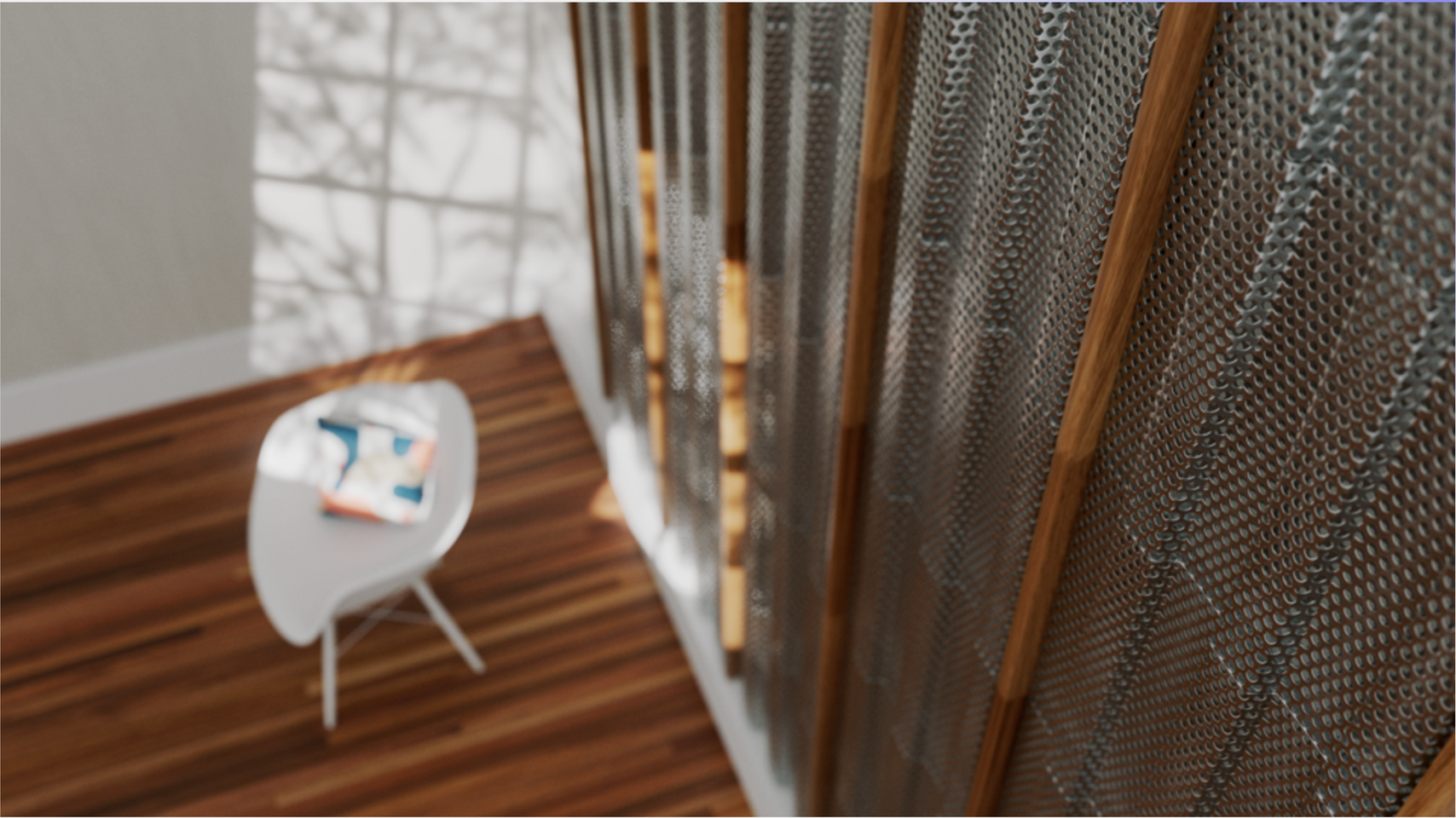

Seamless In-House Integration for Faster Turnaround:

-

By handling stamping, coating, and assembly in-house, we cut transfer risks and communication delays. This results in shorter, more reliable lead times and higher yield rates, especially for high-volume production runs.

-

-

-

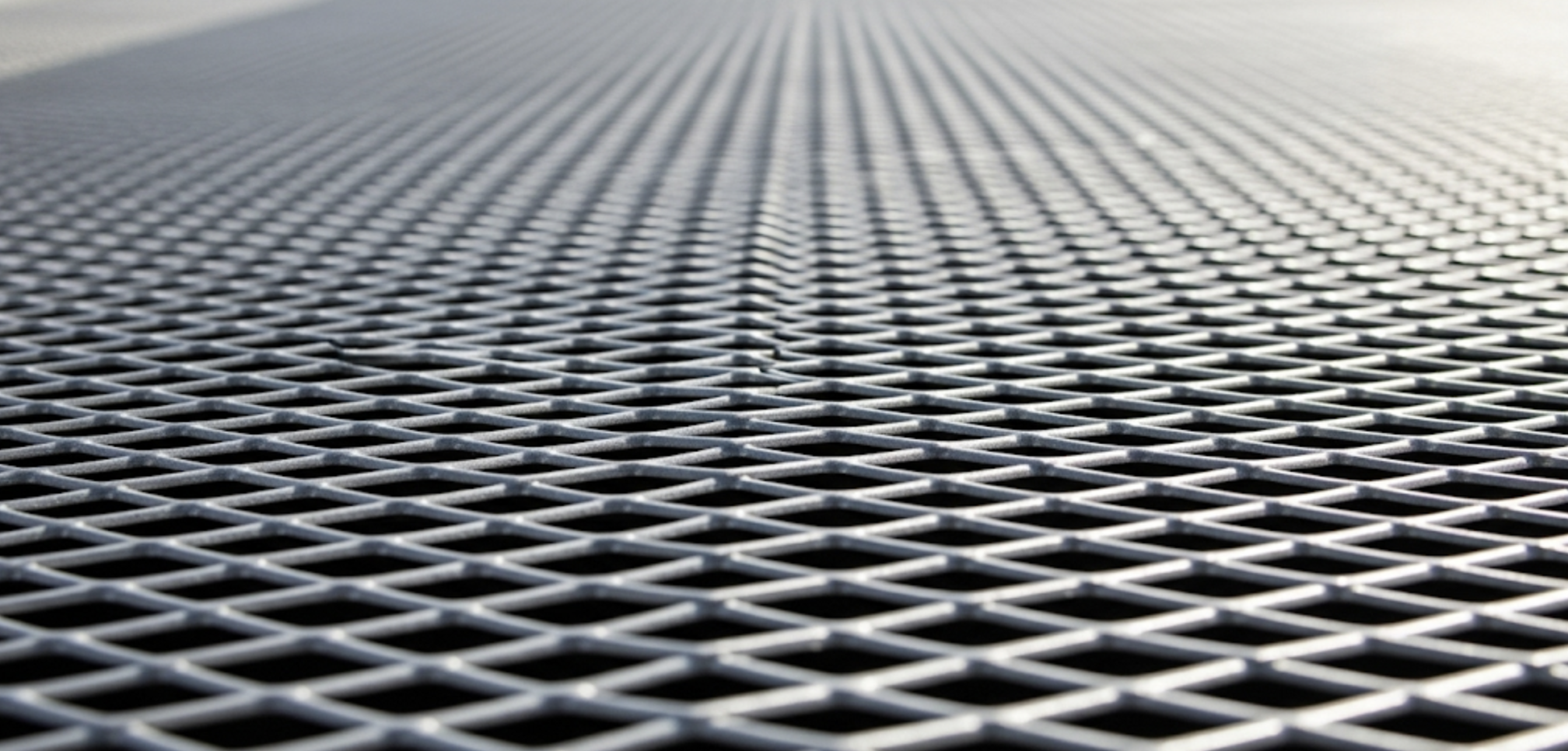

Expertise in Complex Geometries & Materials:

-

From deep drawing stainless steel to forming multi-angle aluminum profiles, our engineering team and in-house die manufacturing capabilities excel at producing high-precision components with tight tolerances.

Core Stamping Capabilities & Equipment

Press Range

~200 tons

(Progressive & Transfer Stamping)

Process Control

ERP Production Tracking

CMM & Optical Inspection

Forming Capabilities

Curved Surface Forming

Multi-Angle Geometries

Complex Profiles

Product Portfolio